The European Commission prescribed in the ’Directive 2006/21/EC of the European Parliament and of the Council on the management of waste from the extractive industries’ (Mine Waste Directive; MWD) that the Member States shall ensure that an inventory of closed waste facilities, including abandoned waste facilities, located on their territory which cause serious negative environmental impacts or have the potential of becoming in the medium or short term a serious threat to human health or the environment is drawn up and periodically updated (Article 20). The risk-based inventory of the mine waste facilities has to be made public by 1 May 2012. The Hungarian decree of 14/2008 (IV. 3) GKM adopting MWD referred the inventory, environmental risk assessment and ranking to the competence of the mining authority.

In order to comply with the EU and national legislation, the Eötvös Loránd Geophysical Institute (ELGI), in co-operation with the Geological Institute of Hungary (MAFI), has delivered the inventory of mine waste facilities in Hungary, according to contract by the Hungarian Bureau of Mining and Geology (MBFH).

In the common use, mine waste facilities are called ’mine waste heaps’ in the case of unprocessed coarse rock, while they are called ’tailings’ in the case of processed fine-grained mud.

The materials of these facilities get to the surface from the underground by mining or excavation, often causing environmental contamination. These facilities have to be studied and their environmental risk has to be identified and, if justified, the necessary actions have to be implemented to reduce risk.

The first step in the implementation of the inventory was the acquisition of the necessary archive data. This includes the basic spatial, environmental and demographic acquisition and harmonization in a database system; in addition to the review of all closed mine waste facilities and visualization in maps. Also, the data on the facilities necessary for the risk assessment has to be collected.

The pre-screening method used in the first phase of the risk assessment, according to the EU Guidance, is based on the known environmental impacts and on the study of the source-pathway-receptor chain. The study of the source includes the characteristics of the facility (material stored, engineering stability), the pathway includes the transport means of the released contamination, and the receptor describes the effect of the contamination on sensitive receptors (humans, waters, protected areas, and agricultural areas).

The ’precautionary principle’ is the most important aspect of risk assessment. Accordingly, if uncertainty emerges in data or in the risk ranking of the facility, the facility should be regarded as risky and classified for further examination.

Facilities not passing the preliminary risk screening (pre-selection) and classified for further analysis should be processed in the next step for risk-based ranking (selection). There is no standard method available in the EU for risk-based ranking currently, and it relies on the Member States. In the present approach, the character of the facility (tailings or waste heap), the status of remediation, the size of the facility and the slope of the underlying topographic terrain is used to develop risk classes defining the risk rank of the facility.

In order to improve the presentation efficiency, the ranking was simplified to the status of remediation and the facility size for visualization. For classes were developed both for tailings and waste heaps, emphasized by color coding (see below). The rest of preliminary screening (pre-selection) and ranking parameters can be inquired as facility attributes in the internet application.

The report providing more detail on the inventory and environmental risk assessment of the closed mine waste facilities in Hungary are available at the following URL: Summary Report

The table at the end of this page shows the risk-based ranking (selection) of the closed and abandoned mine waste facilities (based on the data available in April 2012) using the pre-selection and selection questions (parameters).

References

STANLEY G., JORDÁN GY., HÁMOR T., SPONAR M. (2011):

Guidance document for a risk-based pre-selection protocol for the inventory of closed waste facilities as required by article 20 of Directive 2006/21/EC

JORDÁN GY. (2011):

Guidance document for a risk-based selection protocol for the ranking of closed waste facilities, a Hungarian recommendation

Registry and visualization

The unified database of landscape wounds, mines, waste heaps and tailings has 16 451 facilities. Only a fraction of this figure, ca. 1 689 facilities, is a closed waste facility, i.e. waste heap or tailings. Among these, 463 facilities can be regarded potentially risky due to the composition of stored material that is not neutral in effect, or it can even be toxic to living organisms (at the time of the internet publication of results on 01 May 2012).

According to the pre-selection, 44 facilities do not need further examination. Selection, the risk-based ranking has to be performed on 416 facilities. For 106 waste facilities had information available on the status of remediation, and for more than 310 there is no information on remediation. A significant portion of these facilities are historic heritage, i.e. facilities closed decades ago, where a significant environmental impact has not been observed.

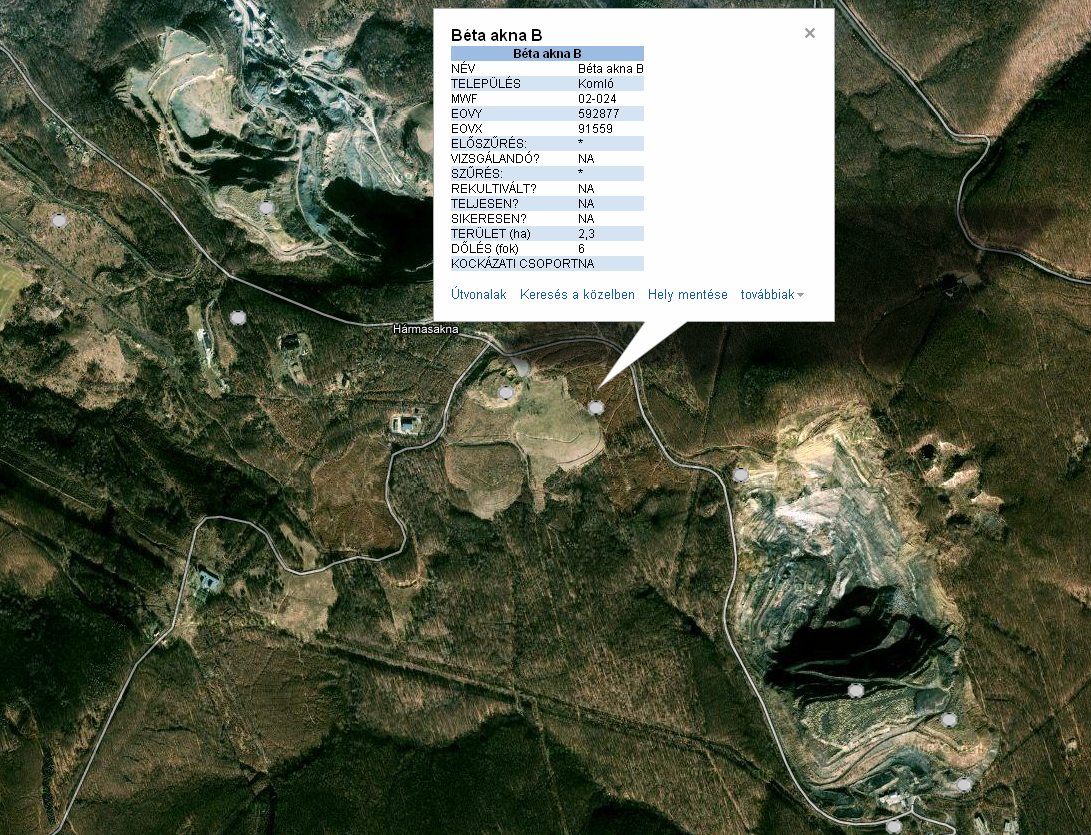

At the link below, mine waste facilities processed through the pre-selection (grey dot) and selection (dot of various colors) procedures are shown. Color coding shows ranking-based classification. Besides color codes, results of pre-selection and answers to the questions of selection are also shown by clicking at the facility.

The facility attribute table scrolling down

at a click under 'Google maps'

Attribute description

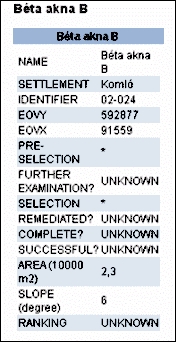

1) HEADER:

NAME: The short and informative name of the facility that may refer to its location and character, or even to the mined mineral;

SETTLEMENT: Settlement located the closest to the facility;

IDENTIFIER: Unique ID of the facility;

EOVX, EOVY: Geographic coordinates of the facility in the National Metric Projection (EOV) system. Spatial objects have their centroid coordinates;

2) RESULT OF PRE-SELECTON:

FURTHER EXAMINE?

- Yes, if hazard of material or facility stability exists, besides hazard of transport and receptor are present, too.

- Unknown, shows uncertainty due to lack of data, and it is identical to ’Yes’ according to the precautionary principle.

- No, in the lack of material or facility stability hazard, or in the lack of pathway or receptors.

Thus, the result of pre-selection for a facility can be either no need for further examination, or need for further examination, based on the data or due to lack of sufficient information (precautionary principle). If the facility is selected for further examination, the facility has to be further examined in the selection procedure.

3) RESULS OF SELECTION:

REMEDIATED? Has remediation been carried out for the mine waste facility?

- Yes, if any remediation activity has been performed.

- Unknown, no data.

- No, if the facility has never been processed for remediation.

COMPLETE? Has remediation been done for the whole facility, or only for a part of it?

- Yes, if remediation extends to the whole area of the facility.

- Unknown, no data.

- No, if not the whole area has been remediate, or if there are areas of the tailings/waste heap not remediate (or still active) parts.

SUCCESSFUL? The question asks about the result of the remediate part of the facility: was it successful?

- Yes, if no further action is required.

- Unknown, no data.

- No, if remediation has failed or it has to be remediate again.

AREA: Area of the waste facility based on archive data, topographic maps and remotely sensed images. The larger the facility the higher amount of contamination material is likely to be present.

SLOPE: Topographic slope below the facility. The steeper the slope the higher is facility instability and contamination transport probability.

RANKING: Besides stored material, engineering stability is very important, especially for tailings. For this reason, the tailings area classified in the highest risk ranking category, independent from the stored material. An accidental dam breach, the mud flow can cause loss of lives or causalities. For risk-based ranking, both for tailings and waste rock heaps, the following classification is used:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|